Corporate

ELEKTROTEKNIK

ELEKTROTEKNİK KLİMA is operating since 1988 and pioneered Turkey's heating, cooling and ventilation sector. With the investments in this area, our company became one of the leading producer in the World and in Turkey.

About Us

Elektroteknik is growing every year and become leader in Turkey with the investments of HVAC equipments, Fire and Smoke control systems, Clean Room solutions, tunnel, and underground ventilation equipments. Thus, our company became one of the most important and successful producers in Europe.

With more than 300 employees and the expert staff, the company operates in four different production facilities in Eskişehir organized industrial site and in İstanbul. Elektroteknik is respectful to human and environment, entrepreneurship in the sector and one of the most important industrial enterprises in Turkey.

Elektroteknik Klima is 1st in the sector in Turkey, also between the top 10 companies in Europe as production and sales capacity. Elektroteknik is exporting to 47 different countries, has a good international outstanding and 100% native owned Turkish company.

Overview

Foundation Year: 1988

Total Closed Production Area: 90000 m2

Number of Employees: 350 (2016)

History

1988-2005

Elektroteknik was established in 1988 in Istanbul, Dudullu organized industrial site and considered the changing market conditions. According to this, the company has taken decisive steps in the sector. In this direction it has increased engineering power and made investments in human resources, created collaboration. To receive the results, company made test studies, Research& Development and achieved international certifications. Results of investments brought the ability of designing, producing products in international standards and to turn into an advantage of expanding market opportunities. Performing R&D studies made Eektroteknik Klima a leading company and made innovations in the sector.

At the end of 1999, Elektroteknik started to attend to International fairs and conferences regularly and featured its own knowledge. So, this made the company more powerful in the market.

In 2004, Elektroteknik continued to operate in 4500m2 closed production area with the production staff of 80 people.

After development process in 2005, the company has moved to a closed production area which is 12.500m2(production) and 2000m2(office) in Eskişehir organized industrial site. In this way, production capacity and logistics network increased four times. Eskişehir became an enterprise zone and regional production power increased.

At the beginning of 2009, new facility which is 8500m2 in İstanbul, Dudullu has begin to operate and with this progress increased the company’s production 20% and expanded logistics networks.

2010-2015

Elektroteknik’s main goal at the present time is to protect the position in the national marketplace, develop in international market and become one of the first 10 producing company in Europe

At the end of 2010, in Eskişehir organized industrial site, the second closed building with 8000m2 has started to process with new production lines and air distribution equipments.

By this way, Elektroteknik became one of the biggest HVAC equipment producing company with production capacity in global market under one roof.

At the end of 2010, number of employees of production staff increased to 200 from 80. As a result of this, company provided serious employment. Furthermore, market share increased 30% and achieved more than 50% national market share.

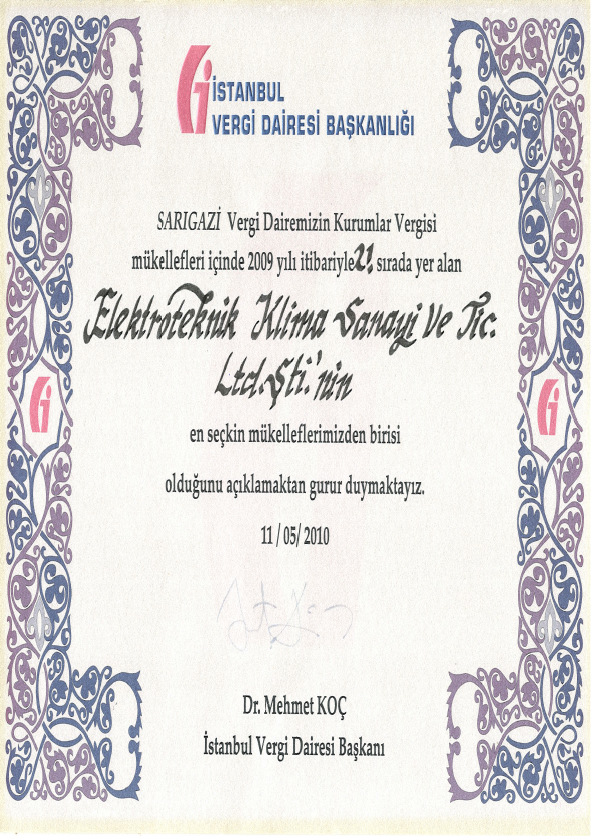

In 2010 Elektroteknik was rewarded by the ministry because the company was between the first 20 company within the region according to the tax order. At the same time besides the production capacity, investments in technical areas also raised.

One of the most important need in national sector was fire legislations and the changes due to this, Elektroteknik started investments, research and development studies about fire dampers with international certifications.

In 2011, YD200 and YD400-S fire dampers completed the British Standard of fire tests and gained the certification of BS476:20, which made the company first certificated producer in Turkey.

As a result of Istanbul Technical University’s studies that took 4 years, Elektroteknik became one of the first company that supported hydrogen boats projects in Turkey.

In 2012, EN1366-2 certificated fire and smoke damper YD300 started to produce. Again in this period, Elektroteknik was first EN certificated company in Turkey and of the 8 company in Europe.

In 2012, a seminar was organized during TTMD Istanbul agency organization about fire dampers and their international standards. Also, a technical trip was organized to Eskişehir production facilities with the participation of professionals from the sector.

At the end of 2012, market share was 20% increased and more than 60% of national market share was gained and Elektroteknik became a regional trademark. Also, for a different group of technical production, construction of the third facility with 12500m2 closed production area in Eskişiehir has started. Therefore, total closed production area became 34000m2 and the number of total employee was more than 250.

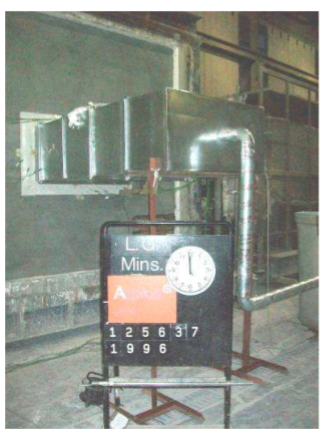

At the same year, research and development facility investments have began. EN12101, ISO 7726, ISO7730, DIN 1946-2 norms applied to activate test rooms with international standards.

In 2013, new product of fire and smoke damper YD300 began to produce. Certifications of EN15650 and EN13501-3 became the highest performance class and the new product code YD300 was changed as YD300-EU. Also, new fire and smoke damper with EIS120 performance started to produce and this was first in Turkey and the company became one of the first 10 company in Europe.

In 2014, research and development studies about fire security continued. To create a new market American Standards about this topic was studied and YD200 fire dampers were tested according to American Standards. In this way, Elektroteknik became first UL555 certified Turkish producer and this made the company one of the counted companies in the World. Hereby about fire and smoke dampers, Elektrotenik became the first company in the World with three different standards which are; English, American and European. Elektroteknik Klima is the only company in the World with these certifications and the ability of production under one roof.

At the same year, the company continued ventilation system projects about tunnels and undergrounds and became Europe’s first production company with 6 different certifications. Also, company had a role in important projects like Eurasian Tunnel.

In 2014, the type of the company changed as ‘Joint-Stock Company’.

In 2015, the plans of physical investments and activities continued. According to the new product plans, the company has decided to make and investment for a facility in an area of 105.000m2 which is an integrated production facility of 73.500m2 and 39.000m2.

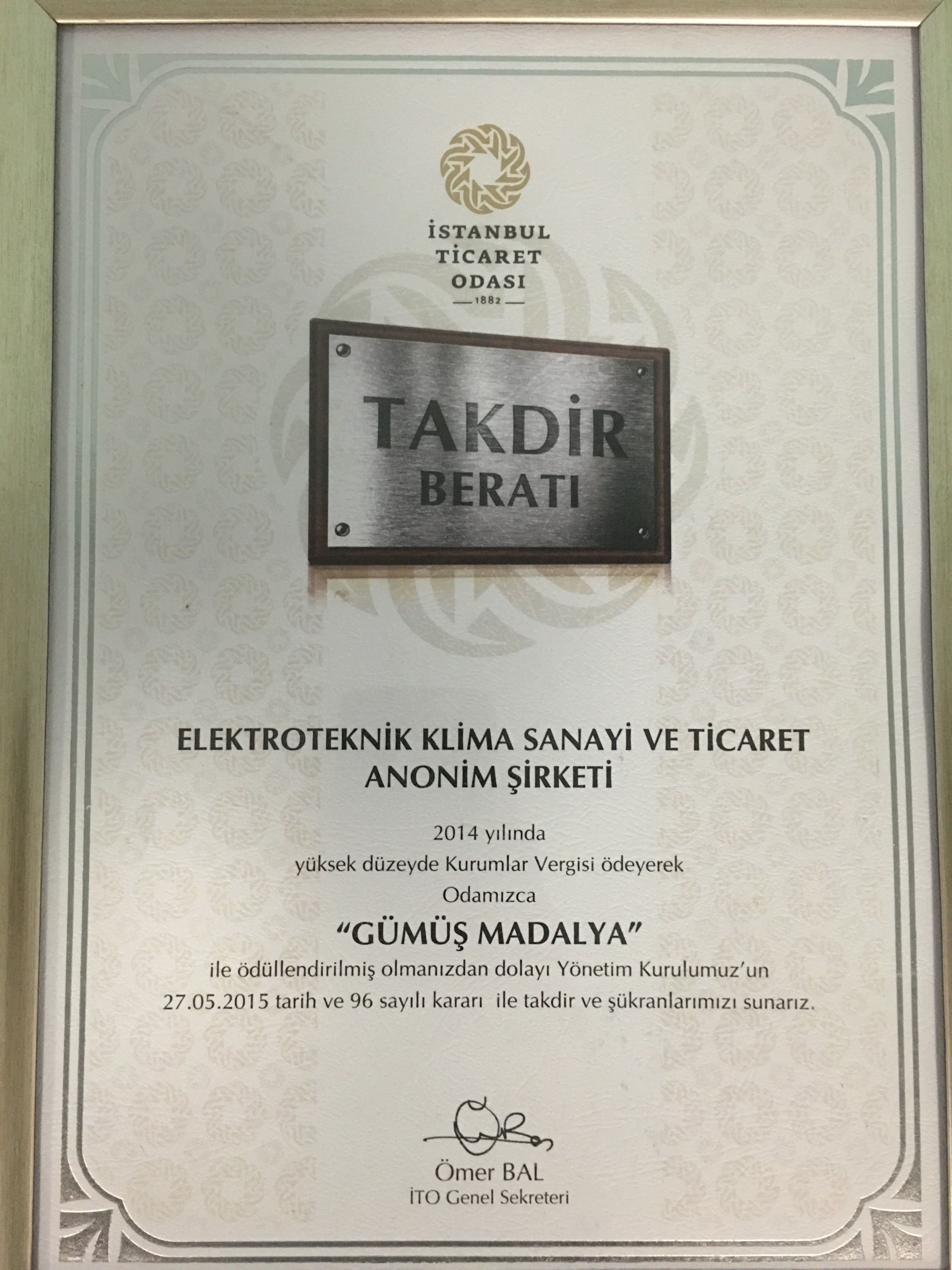

In 2015, Istanbul Chamber of Commerce gave a silver medal as a reward because of tax payments and the position of company between other companies in Istanbul and related region.

2016- …

In 2016, the construction of 1.phase of integrated production facility was completed and full automation equipment investment plan was started. From 2016, the company has provided employment more than 350 employee and started to use broad sub-industry.

At the present time, Elektroteknik is exporting particularly Romania, Turkmenistan, Azerbaijan, Kazakhstan, Russia, Bulgaria, Ukraine, Cyprus, Poland, Croatia, Georgia, Greece, Egypt, UAE, Italy, Spain, France, Israel, Tunisia, Algeria, Moldova, Ireland, Serbia, Czech Republic, Iraq, Kosovo, Finland, Uzbekistan, Portugal, Hungary and 42 different countries.

In the modern production facilities, predominantly automation techniques minimize faults with high quality productions. Also, with board logistic department, shipping and storage areas made the company pioneer in the sector. Not only in domestic logistics but also in overseas shipping, Elektroteknik is organizing the logistics with the principle of zero mistakes.

Products, production and the quality of organization are certified by many certifications like TSE, ISO, CE and this made Elektroteknik the leader of the sector. And so the company shall protect its position and provide service in Turkey and globally with the growing product range.

Strategic Outlook

Our Mission

Our main mission is to keep our production at the highest level and enhance native production at an international level. Become a master brand in the sector. According to the needs of the sector, increase product range and present them with competitive prices. Creating valuable services to our customers is crucial. Creating an active organization with ethical standards, we are trying to answer the needs of the market with the principle of reliability. With the contribution of our employers we are trying to serve our customers with high quality products in service concept.

Our Vision

Initially, we follow technological developments, innovations and determine them. Afterwards we start to produce and try to present them to our customers. Each passing day, our departments expand with new product ranges. Thus, with our reliable name we are experiencing the pride of our company’s achievements. As today, in the future our main vision will be to protect our leading name in the ventilation sector and to follow our values which is leading the steady growth of our company.

Our Values

Reliability and Honesty

With professional ethics and discipline we show model behavior. In relationships and in business we stick to the facts and disillusions, keep our promises and always deliver commitments.

Customer Sensitivity

To understand existing and future expectations of customers and remaining steady creates happy customers. Specifying needs of the customers at the correct time and understanding them correctly is important. We are responsible from the problems of our customers and start to produce solutions to avoid repetition. So, producing services and high quality products to meet the expectations of our customer future and existing needs is our main goal.

Continuous Development and Quality Oriented

We are supporting development by following innovations, difference making suggestions and new applications. Determining performance standards for high quality and trying to achieve them is company’s main development value. For continuous improvement we search the new developments, new ideas and technological applications, apply them and reflect them to our projects.

Be Dynamic

Reflecting positive energy to our environment, creating excitement effects work environment positively and get fast targeted results. Determination to succeed, even under hard circumstances brings success. Always moving towards the result promotes productivity and help seeing beyond the work.

Have Confidence

We trust our knowledge, skills and abilities and we have the courage to share and defend our view and ideas with others. Our company is enthusiastic about having responsibilities about different tasks even the ones which other people are hesitant about.

Production Facilities

Istanbul Central Office and Certified Products Production Facility

Total Area: 10.000m2

Total Closed Production Area: 8.500m2

Total Closed Storage Area: 1.000m2

Production Groups: Certified fire dampers, stainless hygienic products

Eskişehir Central Office and Steal Sheet Engraving Facility

Total Area: 25.000m2

Total Closed Production Area: 12.500m2

Total Closed Storage Area: 2.000m2

Production Groups: Air Control Dampers, Filter box, Plenum box

Eskişehir Air Distribution Equipment Production Facility

Total Area: 10.000m2

Total Closed Production Area: 8.000m2

Total Closed Storage Area: 1.000m2

Production Groups: Diffusers, Vent groups, Vent Louver Groups

Eskişehir Technical Products Production Facility

Total Area: 25.000m2

Total Closed Production Area: 12.500m2

Total Closed Storage Area: 2.000m2

Production Groups: Ground convectors, VAV/CAV systems, noise control equipments, Splitters, Special product groups.

New Investments

Full-Automation Paint Facility

During 2016, in Eskişehir production facility, Elektroteknik has started to produce full-automation homogenous paint without human touch in 1500 m2 area.

Eskişehir Integrated Production Facility Phase1

The project and the construction which was started in 2015 have completed in 2016 and full automation production line investments are under consideration.